Top-quality milling and drilling ...

with our new horizontal machining centre

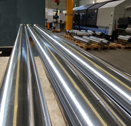

“We’re not going to let the coronavirus crisis deter us from our long-term growth and development plan,” says BüMi’s CEO Frank Mittag as he marks the start of a new year. The signs could not be clearer: BüMi has continued to invest in a real “heavyweight”, the DMC 160 U duoBLOCK machining centre. Components with a unit weight of up to 3 t and measuring 1,600 x 1,250 x 1,000 mm can be produced on the NC rotary tables with pallet changer.

The duoBLOCK principle guarantees more stability and greater accuracy, while the Siemens 3D path control system (840 D Powerline ShopMill), the direct path measurement system and the automatic swivelling milling head enable horizontal and vertical machining with up to 60 tools in the rack magazine.

The increased coolant supply at up to 80 bar allows for efficient drilling.

The former storeroom has been turned into a new milling area due to the large amount of space required and the weight of the machine, making the best possible use of the facility. This represents another step into the future for BüMi.

Januar 2021