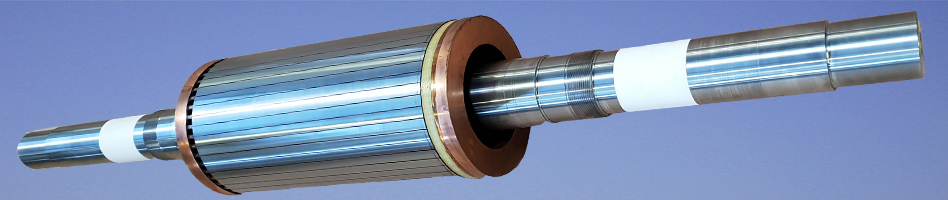

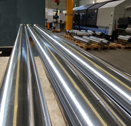

We can handle induction surface hardening up to a diameter of 500 mm and a length of 6,000 mm as well as the subsequent tempering in a furnace.

We can handle induction surface hardening up to a diameter of 500 mm and a length of 6,000 mm as well as the subsequent tempering in a furnace.

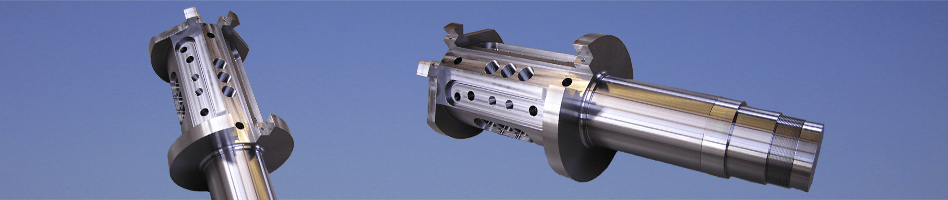

This enables us to offer short throughput times and a monitored high level of quality even when working with hardened components. Our straightening press allows us to correct any distortion caused by the hardening process without delay. Additional heat and surface treatments are carried out by other accredited specialists, with priority given to firms local to us.

By selecting suitable companies and undertaking continuous quality monitoring, we can offer good quality at competitive prices at all times.

Here is a selection of possible treatments:

- Quenching and tempering and annealing

- Case and salt bath hardening

- Nitriding and ferritic nitrocarburizing

- Galvanising and phosphating

- Bronzing

- Anodising and coating

- Painting/varnishing/lacquering and coating

Our fleet of machinery:

| Hardening | EFD induction hardening machine (surface hardness depth in accordance with DIN up to 10 mm) |

up to 500 mm in diameter | up to 6,000 mm in length |

| Tempering | Tempering furnace | up to 300° C | |

| Straightening | MAE S250 RH | up to 250 t | |