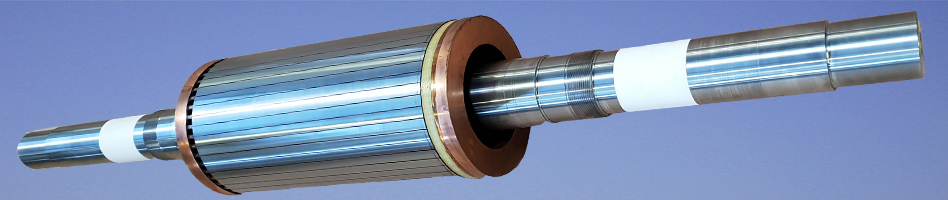

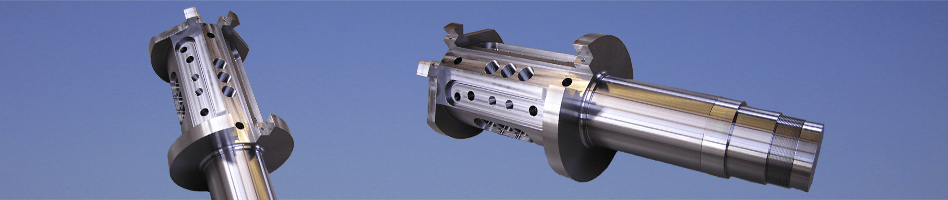

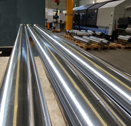

We can supply you with parts machined ready to install and made from virtually any metal – turned, milled, hardened and ground. To do this, we procure the primary materials we need at low cost, including bar steel, tubes, flame- or laser-cut parts and forged or cast blanks. Needless to say, we can also machine unmachined or semi-finished parts for you on a contract basis. We handle induction surface hardening in house, including tempering and straightening up to lengths of 6,000 mm, while other heat treatments and surface finishing are outsourced to accredited specialists that we have verified.

Although the machinery and equipment at our disposal makes us particularly efficient for production batches of between 10 and 1,000 units, we are also more than happy to make single parts, prototypes and small or larger batches for you.

We see ourselves as a business that is focused on its customers. Urgent orders are carried out just as reliably and on time as long-term orders under framework agreements.

We use state-of-the-art testing and measuring equipment, efficient document management systems and extensive monitoring of our outgoing goods to ensure that your quality and documentation requirements are met in full. We are certified in accordance with ISO 9001:2015

Employing a powerful ERP system with integrated company-wide data collection and linking up our machinery allow us to adopt effective, traceable work processes.